The Advanced Lead-Acid Battery Consortium (ALABC) will focus on the Affordable 48V 'Intelligent Electrification' of Next Generation Hybrid Vehicles

|

AUTO CENTRAL, UK -- Sept. 8, 2014: The Advanced Lead-Acid Battery Consortium (ALABC) will focus on the affordable 48V ‘intelligent electrification’ of next generation hybrid vehicles at the 14th European Lead Battery Conference (14ELBC). This new class of hybrid aims to keep the cost down and the voltage below the critical 60 volt safety threshold. Organised by the International Lead Association (ILA), the conference and exhibition is being held this week from 9-12 September 2014 in Edinburgh, Scotland.

“Recent work and results in the design of a new class of low voltage hybrid vehicle will help reduce carbon emissions and bring about major improvements in fuel efficiency,” says ALABC European projects coordinator Allan Cooper, who also works with the event’s organising committee. “This can be achieved using advanced lead-carbon batteries, which currently provide the most cost effective solution for the automotive industry. New data will be published at ELBC on the use of higher levels of carbon in the negative active mass, a development which is resulting in much improved battery performance.”

A keynote presentation on ‘Global Warming and Lead-Carbon Batteries’ to be delivered by Pat Moseley, president emeritus ALABC and co-author of a new book entitled ‘Towards Sustainable Road Transport’, will outline the state of the art in advanced energy storage systems and their impact on vehicle design.

As immediate past president of this international research organisation, Moseley has been at the helm of ALABC overseeing more than two decades of development leading to the breakthrough lead-carbon battery technology, which is now at a high level of manufacturing readiness for forthcoming 48V hybrid vehicle applications.

“We can meet the vehicle OEM cost target of $250/kWh as an alternative to more expensive lithium-ion batteries,” says Moseley. “Moreover, a technical advantage of high power lead-carbon batteries is their ability to handle the high rate partial state-of-charge cycling requirements of 48V hybridisation, thereby maximising the use of fast acting kinetic and thermal energy recovery systems in these vehicles.”

The new battery technology has already been applied to the LC Super Hybrid programme, which includes both 12V stop-start and 48V hybrid demonstrator vehicles. A technical paper delivered by Allan Cooper, will be complemented by a presentation entitled ‘Addressing Market Demands for an Affordable Hybrid System Solution’ delivered by Nick Pascoe chief executive and Paul Bloore product validation manager at Controlled Power Technologies. Both presentations will be delivered in a conference session entitled ‘Lead Batteries for Low Emission Vehicles’.

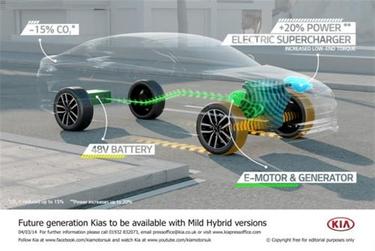

Technology partners ALABC and CPT are also working closely with AVL, which has helped to build the LC Super Hybrid demonstrators. Carsten Kaup manager hybrid and electric powertrain systems at AVL Schrick GmbH will present a complementary paper entitled ‘A 48V Diesel Hybrid with Lead-Acid Batteries is not a Contradiction: It is Reality” which discusses a new 48V Kia diesel hybrid scheduled for display at the forthcoming Paris Motor Show in October – again utilising advanced lead carbon batteries. The Kia development team behind the mild hybrid powertrain selected lead-carbon batteries over lithium-ion equivalents as they require no active cooling, are more easily recyclable at the end of the vehicle’s life and can function much more efficiently in sub-zero temperatures.

And on the same theme, Philip Williams, principal engineer for hybrid vehicles at Ricardo, and project manager for the Advanced Diesel Electric Powertrain project known as ADEPT, will provide a mid-term report ‘on the potential for 48V based intelligent electrification in delivering full hybrid-scale fuel efficiency from a highly cost-effective package’. The ADEPT research team – led by Ricardo and including Ford Motor Company, Controlled Power Technologies, the European Advanced Lead Acid Battery Consortium, Faurecia and the University of Nottingham – has recently completed the build of the first functional integration prototype.

Based on a Ford Focus, this ADEPT prototype incorporates a 48V electrical architecture, a SpeedStart 10kW (later to be upgraded to 12.5kW) belt integrated starter generator and TIGERS turbine integrated exhaust gas energy recovery system, both switched reluctance machines supplied by CPT, with an advanced lead carbon battery pack provided by ALABC.

“The universal application of 48V technology to the global vehicle parc would help significantly reduce annual CO2 emissions from the automotive and transport sector,” says Cooper.

Altogether, the 14ELBC conference will deliver 64 presentations, and selected texts will be published in an edition of the Journal of Power Sources edited by Pat Moseley.